Fully Automatic Solder Paste Printer

In the fields of high-precision printing,high-quality pursuit,and

high-efficiency production equipment capabilities determine the

stability of printing quality and output efficiency and GT mini is

your best choice.

In the new printing scheme of GTmini,with the unique dual-track

module,you can obtain high-efficiency UPH output, and the flexible

matching scheme can also be corverted from HTH mode to single-track

mode at any time,allowing you to have a return on investment Full

of confidence.

At the same time, GTmini is one,so you don't have to worry about

the footprint of printing equipment,because GTmini has a 2:1 ratio of equipment

wiring advantages in the unit footprint of traditional printing

equipment,which is a real unit footprint. Program implementers with

higher area output.

The GTmini, which has high-demand assembly technology can also

allow you to experience better human-computer interaction the "self-awareness

function' with excellent capabilities and the "self-spot"that exceeds the

industry's ability when ensuring the accuracy of the first-tier equipment"Check

function,let GTmini debut in the traditional equipment is the pinnacle.

At the same time, GTmini's dosed-loop system such as:solder paste

residual detection & automatic tin addition real-time pressure closed-loop,

steel mesh adsorption and other functions, not only consolidate printing

stability, but also reduce manual operations for you and improve efficiency And reduce

costs.

On the basis of focusing on equipment capabilities GKG is

more"customer centric"With the support of YUSH process team experts, you can

experience private customized service

plans,including:installation,commissioning,training.maintenance, etc. and will also focus on Your pain point,provide

you with the whole line of operation, product process technology and other

programs.

Choose GTmini, you immediately have the world's top printing

solutions and service solutions team,to escort your EMS journey,win-win future.

High-precision Printing / High-quality Pursuit / High-efficiency Production

GT mini insists on being market-oriented, keeping the wind that

leads the design front, and developing the HTH model vertically.The

two-in-one GTmini covers an area of only: 1500mmx1500mmx1240mm,and

the same-side layout design allows you to be on the production

line. Get a good experience in layout and operation convenience.

Vertically / HTH Model / Two-In-One

Equipment Modules

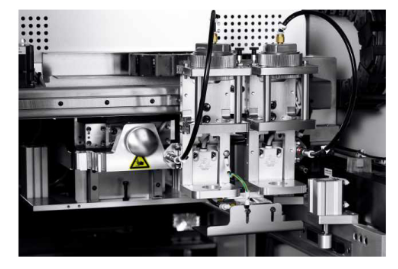

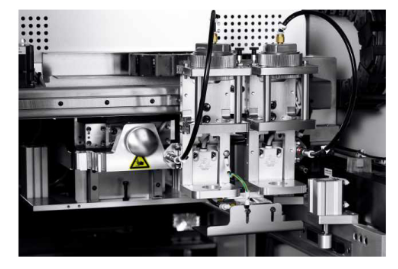

1.Transmission

The dual-track mode of GTmini allows you to worry about the site

and is also excellent in product handling,because 2/3/4-track can

be arbitrarily translated and adjusted. Not only is the setting simple, but also the accuracy is very reliable.

2.Monitoring

The 1.3 million pixel,FOV:10*8m digital camera standard on GTmini

can not only read Barcode through the CSF system, but also obtain

accurate coordinate values within the interval of milliseconds.

At the same time,GTmini's monitoring system can also monitor the

parallelism of the track transmission module in real time and after

equipment maintenance,GTmini's unique "self-inspection

function''can perform inspection on all modules of the

equipment,reducing and reducing man-made for you Error factors for

maintenance and calibration.

3.Platform

The GTmini platform is based on a very stable frame design.With

super torsional stiffness and vibration resistance, as well as the

precision drive modules and high-precision transmission modules it

equips, it lays the foundation for the continuous use of equipment.

At the same time, the unique "position detection" function can

ensure the real-time consistency of the lifting position of the

equipment every time, so that your quality printing is fully

guaranteed,and details are controlled and considered for you from

the root cause.

4.Scraper

GTmini's scraper module adopts the basic settings of pneumatic +

screw direct transmission,re-optimizes the calibration

capability,adjusts the pressure fluctuation to CTcompression to40ms

and the pressure accuracy is guaranteed to be+0.2kg,realizing

real-time calibration and ensuring Constant pressure and data

upload function lay a solid foundation for quality printing.

5.Cleaning

The YUSH process expert team knows that the cleaning of the steel

mesh hole wall is crucial to the printing quality, so GTmini has

spared no effort in setting the steel mesh cleaning link.

Based on the brand-new and optimized Saigang rubber strip the

unigue "Hurricane Eye''cleaning system maintains 99.6% of the

residual tin powder in the hole wall under the consistent multiple

cleaning modes. It is equipped with integrated cleaning (dry Wipe,

wet wipe, vacuum),can achieve a quick and thorough cleaning effect.

And based on the convenience of customers, the thoroughly

pre-installed cleaning structure is equipped with an

explosion-proof and corrosion-resistant alcohol pot weighing

structure. Under the premise of maintenance, it can also realize

the detection and warning of the amount of deaning paper and

cleaning liquid,so as to achieve Cleaning paper control and data

analysis.

Under the above novel and attentive function settings,GTmini's

unique quick-change structure, after your cleaning paper is

exhausted can complete the paper replacement within 8 seconds,

leaving you more time for quality output.

6.Software

GTmini's scraper module adopts the basic settings of pneumatic +

screw direct transmission,re-optimizes the calibration

capability,adjusts the pressure fluctuation to CT compression to

40ms, and the pressure accuracy is guaranteed to be±0.2kg,realizing

real-time calibration and ensuring Constant pressure and data

upload function lay a solid foundation for quality printing.

Dimensional Appearance